Over the decades, FRP reinforcements have been deployed in a wide range of structures, from bridges to tunnels and buildings with high technical requirements. Here are some notable examples illustrating the diversity of their applications:

Road Bridges and Viaducts: Following the pioneering projects in Düsseldorf (1986) and Shinmiya (1988) mentioned earlier, many bridges have marked the history of FRP. The Taylor Bridge (Canada, 1997) remains famous for combining prestressed CFRP and FRP reinforcements in a single 165 m structure [1]. The Val-Alain Bridge (Quebec, 2004) demonstrated that a bridge deck made entirely of FRP could be built without compromising long-term performance [2]. More recently, the Innovation Bridge in Miami (2016) was the first in the world to use closed stirrup frames in basalt FRP alongside FRP bars and CFRP cables – showcasing an optimized hybrid approach combining multiple fiber types [3]. Finally, the Halls River Bridge (Florida, 2019) remains a textbook example for its extensive use of composites, confirming that an “all-FRP” structure can achieve lifespans of over 100 years while significantly reducing maintenance costs [4].

Marine and Coastal Structures: Saltwater is steel’s worst enemy, but not FRP’s. A pioneering example is the Hall’s Harbor pier in Nova Scotia (Canada, 1999) – the first port structure in Canada without steel. It features precast concrete slabs reinforced with FRP bars and hybrid beams combining FRP and steel [5]. More than 20 years after construction, it remains in excellent condition, validating FRP’s use in aggressive marine environments. In the UK, the Blackpool pier (2007) combined steel bars and FRP bars in its structure: steel in protected areas, FRP in zones exposed to sea spray, to enhance durability without dramatically increasing costs. In the Persian Gulf, coastal dikes and quays built around 2009–2015 (e.g., in Doha, Qatar) favored FRP reinforcements to ensure corrosion-resistant structures under harsh marine and tropical climates. These prestigious projects helped popularize FRP in the Middle East.

Tunnels and Underground Works: Excavating a tunnel through reinforced concrete poses a challenge when the concrete contains steel – the tunnel boring machine (TBM) must be able to cut through it. The solution was the “soft-eye” concept: locally replacing steel cages with FRP cages, which the TBM can cut without damage. This technique became widespread in the 2010s. It is estimated that more than 200 tunnel openings worldwide (launch and reception vaults) have used FRP reinforcements for soft-eyes to facilitate TBM passage [6]. Landmark projects include London’s Crossrail (2012), where FRP wall sections allowed TBMs to enter stations without obstructive steel bars, the Doha Metro (Qatar), and more recently the Grand Paris Express in France, systematically adopting this practice. Additionally, in urban railway spaces, some track slabs or station bases were cast with FRP to prevent stray currents from electric rails (e.g., University Square station in Magdeburg, 2005, or the Vienna tramway, 2009) [7].

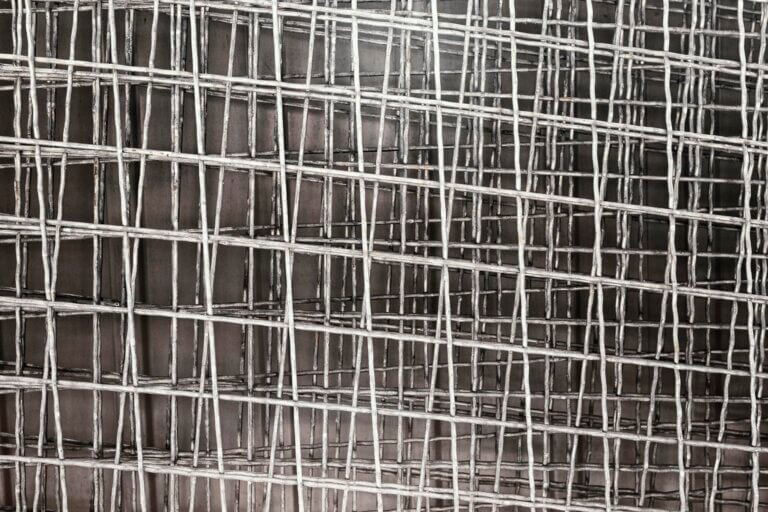

Special Buildings and Parking Structures: Beyond bridges, FRP reinforcements have been used in buildings requiring magnetic neutrality. For example, the Quantum Nanotechnology Center in Waterloo (Canada, 2008) used FRP bars in laboratory slabs to ensure no electromagnetic interference with sensitive equipment [8]. Similarly, the Max Planck Institute in Stuttgart (2011) reinforced certain structures with FRP to maintain a stable non-magnetic environment [9]. In many hospitals, it has become common to reinforce MRI rooms exclusively with FRP to avoid any distortion of magnetic fields – these composite bars being fully transparent to RF waves. On the infrastructure side, the Steglitz Forum in Berlin (underground parking, 2006) was one of the first in Europe to use an FRP mesh (Ø8 mm) over 6,400 m² for the base slab and walls, aiming to prevent corrosion from road salts and reduce concrete cracking [10]. Concrete safety barriers also benefit from FRP: as early as 2008, the Ontario Ministry of Transportation tested highway barriers without steel (FRP bars Ø16 mm) to eliminate rust at anchor points and extend their lifespan [11]. Finally, a historically unique project: the “House of the Future” at Disneyland (1956) mentioned in the introduction. Although built from resin and fibers (without concrete), its dramatic demolition demonstrated how robust composites could be [12] – a visionary nod to the future of FRP reinforcements in construction.

In summary, from sea-sprayed road bridges to ultra-sensitive laboratories, FRP reinforcements have proven their versatility. Each pioneering project removed psychological or technical barriers, gradually advancing the acceptance of these materials in civil engineering. Today, FRP is no longer limited to experimental projects: it has become a credible and proven option for enhancing durability and performance in a wide variety of structures.